Flexible Case Fulfillment for Meat & Poultry

Dematic provides a portfolio of warehouse intralogistics solutions especially designed for the meat protein industry. The solutions manage the specific order fulfillment requirements of the slaughter operations and retail ready/portion pack facilities that supply retailers, wholesalers, food service, and export customers. Dematic solutions for the meat protein industry include pallet and case handling: storage, buffering, sorting, sequencing, picking, palletizing, and reverse route trailer loading.

Operational issues

- Variable inbound flow and buffering of finished inventory

- Production schedule variability

- Products (not always rectangular solid, bone-in)

- Carbon footprint

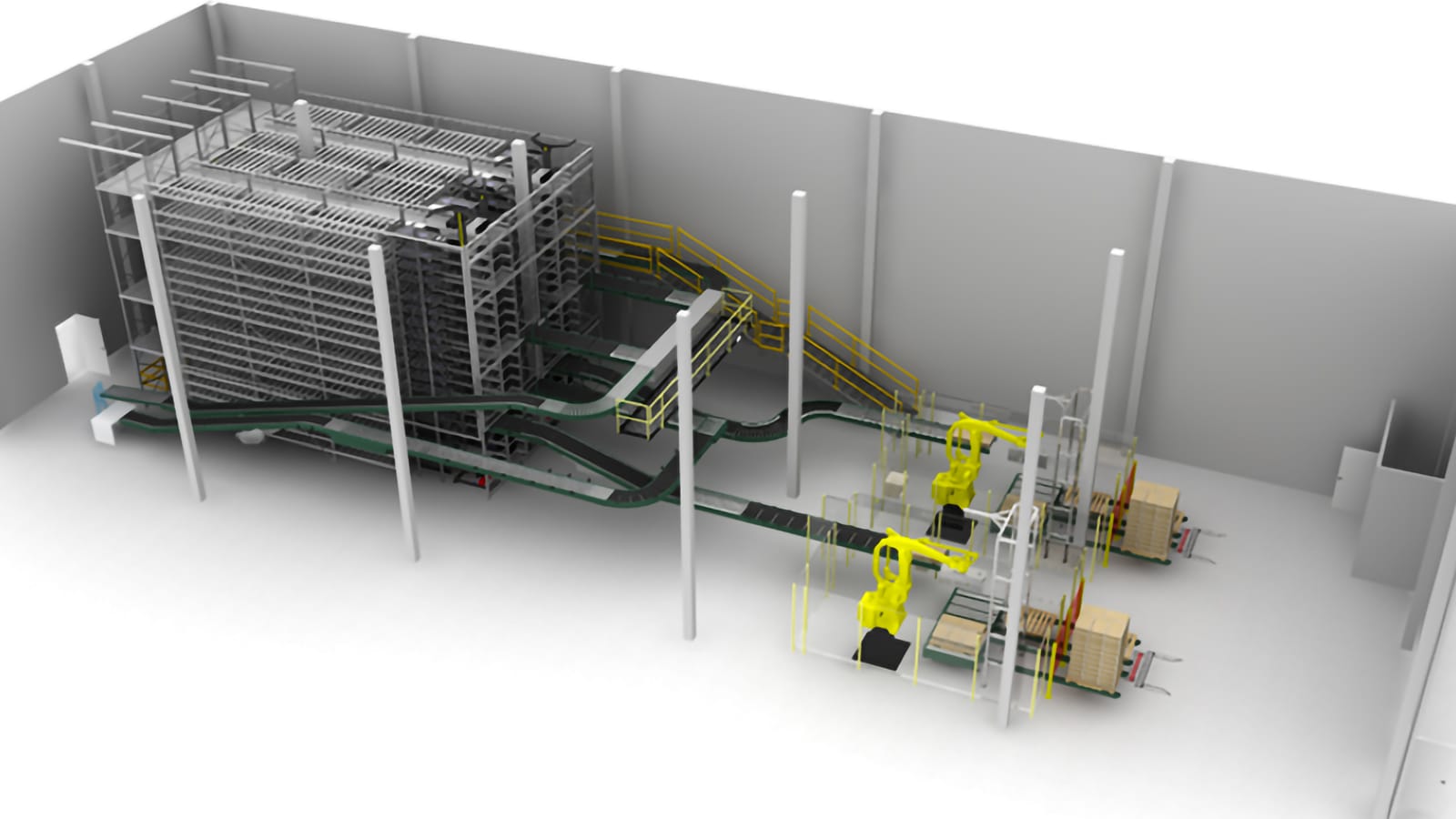

The case pick solution is a modular, standardized, pre-engineered system that provides consistent and predictable case order fulfillment. The execution software synchronizes inventory in the automated shuttle AS/RS to release cases in a precise sequence to palletizing.

Intralogistics solutions

Dematic offers a variety of intralogistics systems that address the operational issues that meat protein producers are experiencing in their production and distribution operations. Dematic solutions provide compelling results by minimizing the time, space, and cost to accomplish order fulfillment. Our meat protein order fulfillment solutions accommodate both chilled and frozen products in cases, totes, and pallets. Each solution addresses increasing requirements to reduce waste and maximize freshness while handling the increasing complexity of customer orders and case sizes. The Dematic Flexible Case Fulfillment for Meat & Poultry solutions are scalable for future changes and growth. The modular automation and software are pre-engineered and standardized to provide consistent and predictable performance.

Replace:

- Labor intensive, manual case pick-to-pallet truck method

- Lifting/handling of heavy cases to minimize potential injuries

Reduce:

- Time to process orders

- Space required with high density inventory buffer storage

- Cost to operate with less: labor, refrigeration energy, damage

Increase:

- Worker safety, ergonomics, exposure to harsh environment

- Food safety, tracking, scan validation

- Throughput volume and productivity

- Capacity to store, buffer, track, sequence, sort, palletize

- Rapid response capability, product freshness

- System availability; minimizing potential impact on production

- Flexibility to accommodate package varieties, sizes

- Value added services: cross-dock pallets, oldest on top

- Customer satisfaction, order accuracy, profit

Order fulfillment buffer

The Dematic Multishuttle is a storage sequencing buffer that stores and retrieves cases of product for order fulfillment. It automatically builds, buffers and pre-sorts all the cases required for customer orders. The Warehouse Execution Software directs the cases to the appropriate storage positions within the Multishuttle rack structure based on location management business rules.

Palletizing

Cases of product are released to palletizing from the Multishuttle in a precise sequence. Some applications require that all the pallets are built with one product code, typical in pork distribution operations. Other applications require mixed case palletizing. Palletizing may be accomplished using labor to stack the cases on pallets. Robotic palletizing is often used for one product code palletizing and for mixed case palletizing.

System management

Dematic's Warehouse Execution Software (WES) that synchronizes the inventory, shuttles, and labor to assemble orders with speed and accuracy. The entire process is optimized from inventory management, automated storage, sequencing, sorting to palletizing, and reverse route trailer loading.

Dematic software is configured to manage order fulfillment based on product codes, case weight, and date to maximize freshness and revenue. Order management, planning, and execution strategies assure efficient and responsive fulfillment. Case storage location and order management strategies are included to optimize the order fulfillment process. The software is scalable and can be expanded or re-configured for future change. Order accuracy and traceability is maintained with scan validation throughout.

Comparison

The Dematic Flexible Case Fulfillment for Meat & Poultry provides higher efficiency in a smaller space. Based on a three pallet order, measuring throughput per work hour and time to complete, the Dematic solution

- Requires 400% less labor than manual solutions.

- Needs 33% less total investment than other automated solutions (smaller building and less conveyor required).

- Provides 15% more annually on business benefits.

Flexible case fulfillment for meat and poultry highlights

- Host interface

- Warehouse Execution Software (WES)

- Inventory & order management by product code, date, weight

- Multishuttle order fulfillment sequencing buffer, temperature controlled

- Robotic & manual assist palletizing

- Modular, scalable, pre-engineered system

- Replaces labor intensive manual case pick-to-pallet truck method