Maximise efficiency with AutoStore empowered by Dematic: high-throughput order fulfilment and high-density storage solutions

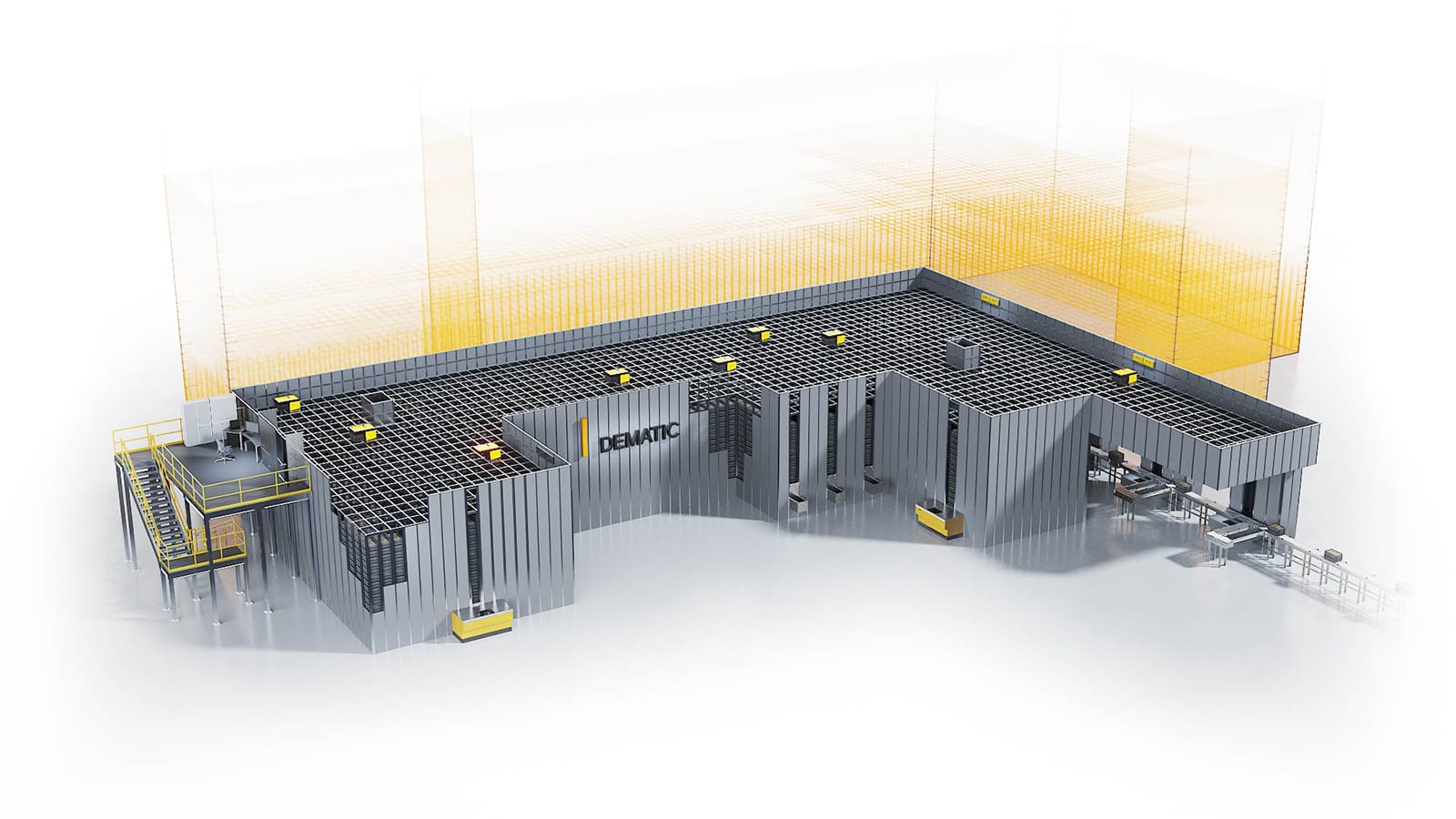

AutoStore is an advanced automated storage and retrieval system (AS/RS) designed for high-density, high-throughput piece-pick and case-pick operations. Its modular grid structure — combined with fast-moving robots — maximises space, accelerates inventory retrieval, and adapts to changing needs, even in cold storage environments.

As a trusted automation partner, Dematic combines its global resources and expertise with AutoStore’s innovative technology to deliver supply chain solutions that empower and sustain customer operations.

Philip Wenger, Director of Technology, NobleWhen you're picking a vendor for something as large as an AutoStore, you have to pick a vendor that's going to partner with you through the difficult times, as much as the easy times, and luckily we partnered with Dematic and they've done a great job in that regard.

Benefits of AutoStore

AutoStore systems, empowered by Dematic, combines high-density piece and case storage with high-throughput automation to transform warehouse operations. As an experienced integrator and software expert, Dematic is uniquely qualified to implement AutoStore systems to achieve superior performance. What’s more, the Dematic Lifecycle Solutions & Services team reaches around the globe to guarantee these AutoStore benefits:

High throughput

AutoStore systems provide fast retrieval and processing of orders. Their efficient use of space and high-speed robots allow operations to meet increasing demands for greater capacity.

Space

AutoStore systems maximise warehouse space by vertically stacking bins, reducing the need for expansive floor areas and optimising storage density. This compact design can save up to 4x the floor space of traditional systems.

Speed and efficiency

AutoStore systems ensure rapid order fulfilment with high-speed robotics. Their quick retrieval and minimal downtime allow operations to meet demands for fast, reliable delivery while improving operational efficiency.

Reliability

The simple, robust design of AutoStore systems minimises maintenance needs and reduces the risk of breakdowns. Their reliability provides continuous operation, even in high-demand environments.

Flexibility and scalability

The modular design of AutoStore systems allow for easy expansion and adaptation to changing business needs. Whether scaling storage or adding robots, the system adapts quickly to operational requirements.

Product safety and security

AutoStore systems provide secure, automated storage that minimise human error by reducing product handling risks. Inventory is stored safely in bins within a controlled, precise manner that ensures product integrity.

Handbook

Evaluation of Goods-to-Person Solutions for Optimised Item Order Picking

This eBook explores in detail the challenges supply chains currently face and compares the leading systems available today. Learn more about:

- The megatrends currently impacting businesses and their supply chains

- How automated goods-to-person systems provide highly efficient order fulfilment

- A detailed analysis and comparison of the technologies, plotting how they fit throughput and storage requirements

- Real-world examples of goods-to-person item order-picking solutions in action

How AutoStore works

AutoStore is a grid of stacked bins with autonomous robots that travel on top the grid and reach into the grid to store and retrieve inventory. The robots bring the bins to workstations (also called ports) where workers pick items for order fulfilment. Chargers ensure the robots are always ready, and the controller manages system operations, coordinating components and optimising the workflow.

Integration capabilities allow AutoStore to work with other systems as part of larger flexible automation solution. Modular design provides redundancy to ensure continuous operation. Globally, AutoStore systems achieve an availability rate of 99.8%.

AutoStore applications by industry

AutoStore systems provide transformative storage, retrieval, and order fulfilment solutions across industries. The adaptable, high-density systems maximise space, increase efficiency, and boost customer satisfaction.

Retail

AutoStore systems optimise retail operations with high-density storage and fast order fulfilment for efficient management of diverse sets of SKUs. Their compact design maximises space in backrooms and warehouses, while their intelligent inventory management ensures popular items are quickly accessible. AutoStore systems boost productivity, enhance customer satisfaction, and support omnichannel strategies for same-day delivery and in-store pickup.

Press Release

Benetton Group Entrusts Dematic with Automation for Key Logistics Facilities in Italy

The Benetton Group achieves its e-commerce objectives with a scalable solution featuring AutoStore, a very compact, easily expandable high-performance storage system with minimal energy consumption and a high degree of security.

Why you should choose Dematic for AutoStore solutions

Dematic is a trusted partner with deep experience in advanced robotics, warehouse systems, and intelligent software. Dematic’s end-to-end approach optimises workflows and maximises operational agility.

AutoStore solutions empowered by Dematic specifically reduce costs, boost efficiency, and pave the way for a smarter future.

Dematic is a trusted partner throughout the entire process, from developing a strategy through implementation and operation. Dematic provides solutions that meet your specific challenges, combining standardised sub-systems with deep industry knowledge to deliver integrated hardware, intelligent software, and end-to-end services.

Dematic works with you at every step to grow your business, win customer loyalty, and deliver at speed and scale worldwide.

Frequently asked questions

An AutoStore system is a high-density, cubic AS/RS where bins are stacked vertically in a grid and accessed by robots that travel on the top layer of the system grid. Robots retrieve bins and deliver them to ports for picking or replenishment.

The main components of an AutoStore system are:

- Grid: The aluminum framework within which bins are stored.

- Robots: Autonomous vehicles that travel on top of the grid to retrieve and transport bins.

- Bins: Containers that hold inventory.

- Workstations (Ports): Areas where bins are delivered for picking inventory and replenishing inventory.

- Controllers: The central processing area where the software that manages system operations and communicates with other systems, such as warehouse management systems (WMSs).

Yes, their modular design allows for easy expansion by adding more grid, robots, or ports without disrupting existing operations.

Yes, The AutoStore Multi-Temperature capability provides storage for ambient, refrigerated, and frozen goods. To minimise space and save energy, a single grid can have sections with different storage temperatures. Or a grid can be a single storage temperature, for example, frozen-only. Multiple frozen temperature grids can be added side-by-side to expand capacity. AutoStore Multi-Temperature capability is especially well-suited for grocery and healthcare operations.

AutoStore's High Throughput capability enables e-commerce customers to store more and fulfil faster even with space constraints. With the ability to store over one million bins, you can have nearly unlimited storage for all of your SKUs. The AutoStore ports enable fast throughput to fulfil orders in seconds, not hours, to meet peak demands of holidays and other surge shopping days.